The Role of Rotors and Drums in Brake System Efficiency

Let’s explore exactly how rotors and brake drums contribute to braking performance, why proper brake maintenance is essential, and how procedures like rotor resurfacing help extend the life of your vehicle’s braking system.

Understanding Brake System Efficiency: More Than Just Stopping Power

Brake system efficiency isn’t just about how fast your vehicle can stop; it’s about how consistently and reliably it does so under different conditions. Efficiency means your braking system can:

- Convert kinetic energy into heat with minimal loss of control

- Distribute braking force evenly across all wheels

- Maintain effectiveness over time and repeated usage

- Avoid brake fade and vibration

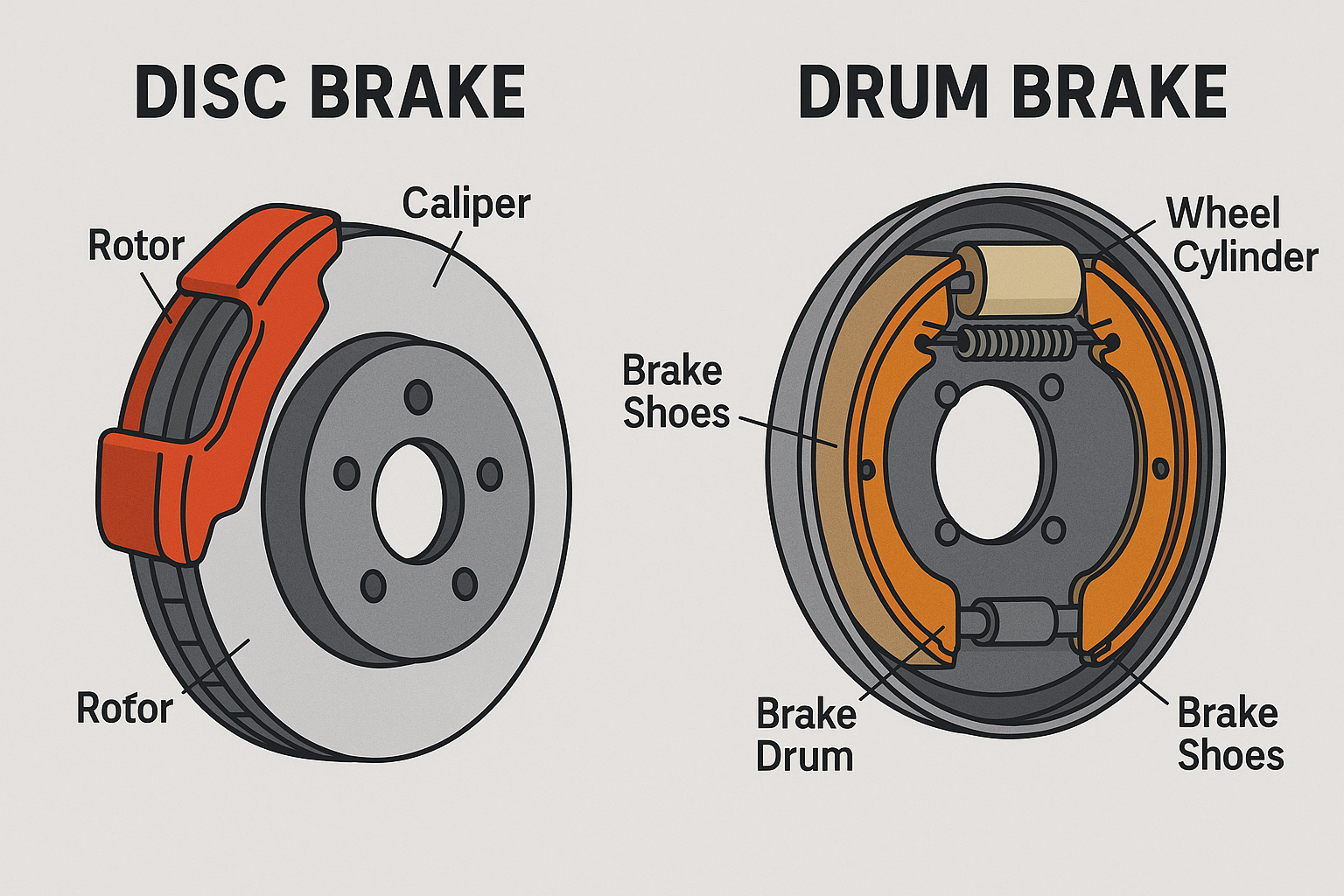

Both rotors (used in disc brakes) and brake drums (used in drum brakes) are responsible for the friction that slows down your wheels. If these components are compromised, warped, grooved, corroded, or overheated, it leads to longer stopping distances, uneven braking, and increased wear on other parts of the system.

How Rotors Impact Brake Performance

Rotors are flat, circular metal discs attached to your wheels. When you apply the brakes, the calipers squeeze the brake pads against the spinning rotors, creating friction that slows the vehicle.

Key Benefits of Well-Maintained Rotors

- Consistent Braking Force: Smooth, even rotors maintain continuous contact with the brake pads, preventing jerky or uneven stops.

- Efficient Heat Dissipation: Vented rotors are designed to dissipate heat quickly. Excessive heat is one of the leading causes of brake fade, especially during heavy or downhill braking.

- Improved Pad Longevity: Warped or rough rotors wear out pads faster. Maintaining rotor integrity ensures that pads don’t develop hot spots or get prematurely degraded.

Rotors can wear unevenly over time due to aggressive driving, lack of brake maintenance, or issues with caliper pressure. That’s where rotor resurfacing comes into play.

Rotor Resurfacing: When Replacement Isn’t Necessary

Rotor resurfacing involves removing a thin layer of the rotor surface using a lathe to eliminate grooves, warping, and irregularities. It’s a cost-effective alternative to full replacement if the rotors are still within the manufacturer’s minimum thickness specs.

Why Rotor Resurfacing Matters

- Restores Contact Surface: Smooth rotors allow for optimal pad-to-metal contact, enhancing brake responsiveness.

- Reduces Vibration: Warped rotors cause noticeable pedal pulsation or steering wheel shake. Resurfacing resolves this.

- Improves Safety: Proper rotor geometry is essential for maintaining even brake pressure and control during hard braking.

It’s essential that rotor resurfacing is performed by a qualified technician using precision equipment, as uneven cuts or excessive removal can compromise rotor strength.

The Underestimated Value of Brake Drums

While many modern vehicles use disc brakes on all four wheels, brake drums are still widely used, especially in rear braking systems of trucks, SUVs, and economy cars.

Brake drums house brake shoes that press outward against the drum’s interior when braking. Because of their enclosed design, drums generate more braking force with less hydraulic pressure, making them especially effective for rear braking and emergency brake systems.

Functional Advantages of Brake Drums

- Durability: Brake drums tend to last longer than rotors due to their thicker structure.

- Lower Maintenance Frequency: Drums wear more slowly and are less exposed to elements, though they still require periodic inspection.

- Emergency Brake Integration: Most parking brake systems use the drum mechanism due to its holding power.

However, brake drums are prone to issues like glazing, cracking, or losing roundness over time, which affects brake system efficiency.

Why Brake Maintenance Shouldn’t Be Skipped

Consistent brake maintenance is the most effective way to protect both rotors and brake drums, ensuring they function optimally throughout their lifespan.

What Comprehensive Brake Maintenance Includes:

- Measuring rotor thickness and drum diameter to ensure components remain within legal safety limits

- Inspecting brake pads and shoes for uneven wear

- Cleaning and lubricating moving parts to prevent sticking or binding

- Checking brake fluid for moisture and contamination, which can corrode calipers and cylinders

Brake efficiency declines gradually, so the signs like soft pedal feel, squealing, or a burning smell can be subtle at first. Routine inspections every 10,000–15,000 miles can catch problems early before they compromise safety.

What Happens When You Neglect Brake System Components

Failing to maintain or replace damaged rotors or brake drums can result in:

- Increased stopping distances due to diminished friction

- Vibration or wobble during braking

- Heat buildup and fade, especially during long descents or emergency stops

- Accelerated wear on brake pads, shoes, calipers, and wheel bearings

- Higher long-term costs, since damaged components often affect other parts of the system

Efficient braking isn’t just about power, it’s about reliability. Proper care of rotors and drums ensures that power is delivered precisely when you need it.

Choosing the Right Shop for Rotor and Drum Service

When it comes to critical systems like braking, experience matters. At Kevin and Kayla’s Automotive, serving Galesburg and Oquawka, IL, our technicians take a diagnostics-first approach to every service. Whether you need rotor resurfacing, drum replacement, or full brake maintenance, you’ll receive expert guidance backed by quality parts and workmanship.

Here’s what sets us apart:

- Advanced diagnostic tools to detect rotor warp and drum imbalance

- Precision resurfacing equipment for long-lasting brake performance

- Honest assessments about when to resurface vs. replace

- A commitment to preserving brake system efficiency without unnecessary upsells

So next time you need brake repair, schedule your service with us!